Around 100-years ago Hanhart became Europe’s largest producer and the market leader in the mechanical stopwatch sector, playing a leading role in the German clock industry.

Hanhart began in 1882, as a small watch shop which was opened in the Swiss town of Diessenhofen. Apart from a brief period after WW2, it boasts an uninterrupted manufacturing tradition up to the present day. The company’s breakthrough came in 1924, when Willy Hanhart, the sports-loving son of the founder, launched the first affordable mechanical stopwatch.

In 1938 Hanhart became a pioneer in the production of pilot’s chronographs and with its Calibre 40 paving the way for the development of the now extremely coveted collector’s watches. From the 1950s onwards, Hanhart increasingly focused on manufacturing mechanical stopwatches and consequently attained global reach through their use in sporting time measurement.

Hanhart stopwatches became indispensable at important car races and sporting events, as well as for general school requirements. Hanhart drew on its own pioneering achievements in the late ’90s and launched the legendary pilot’s chronographs as meticulously crafted new editions.

The legend of the ‘Red Button’ comes from the story of a pilot, who’s partner had painted the button with her red nail varnish so that he would think of her always and return safe and sound. This distinctive trademark that has characterised Hanhart since the company first introduced its chronographs in 1938. The button has been painted, in particular to prevent pilots from unintentionally zeroing the stop time.

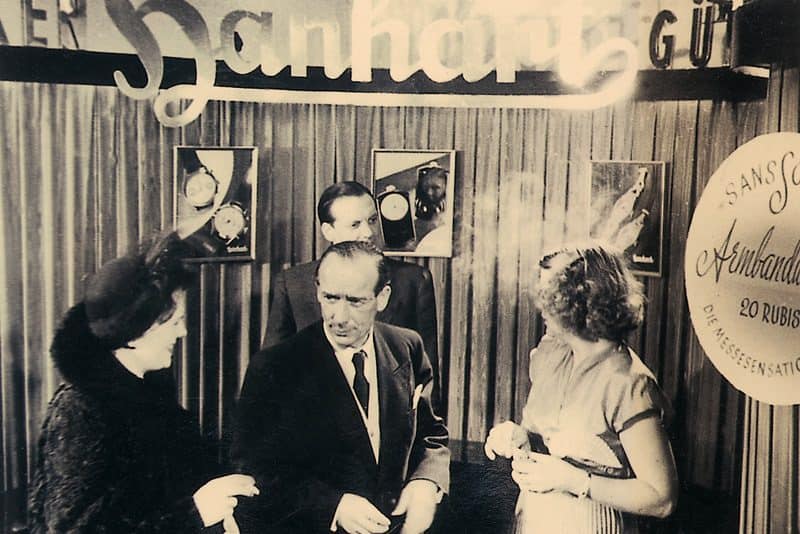

Today, Hanhart’s wrist chronographs are produced in their watchmaking workshop established in Gütenbach, Southern Germany. The factory boasts its own in-house production of tools and manufactures its own parts. From the smallest gear wheels to circuit boards – a great variety of parts for mechanical clock movements are developed and made at this location in the Black Forest.

Over numerous stages of manufacturing, milled, punched or eroded components are first assembled into modules. In the final assembly, the watchmakers piece all the components together and set the dials and hands. The result is high-precision wrist and stopwatches with specially developed additional functions and the quality seal ‘Made in Germany’.

For more information please visit Hanhart